Clamps, and pitch control mechanisms. This threatens propeller structural integrity and performance without being noticed. The overhaul calendar time periods for propellers are established so that the propeller can be disassembled to inspect internal surfaces. Moreover, corrosion acts continuously, regardless of the actual time in operation.

Ideal for small outboard shops, light engineering shops or the home handyman already familiar with welding. These simple tools are used in averaging out the propeller pitch and rake to give very speedy repairs. Practically all outboard and sterndrive propellers to 20 inches in diameter can be aligned with this kit.

(software measures props 9' to 20' although outside this range may be possible) This is a stepping stone for those who wish to get into the propeller repair industry at a low cost then move up to a more advanced system as their needs grow. What items are to be made / included in kits?1.

The Rake Gauge - Probably the most important tool in the kit! When we think of balancing a propeller we automatically think of weight balancing (dynamic). But it's way more important to have the blades straight and in alignment with each other (statically balanced). Blades that are bent or missing pieces will cause vibrations because they are not holding equal water pressure on each blade.

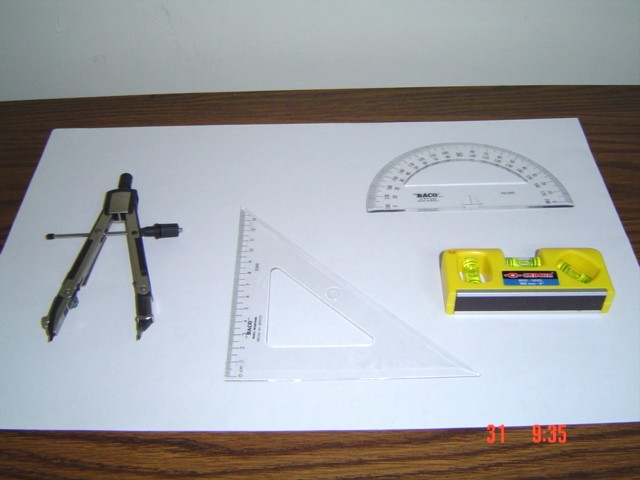

This tool assists in showing you where a propeller is bent and we can also use them to compare rake against new propellers.2. The Pitch Gauge - I use this after I align the blades. We have to ensure each blade is cutting through the water at the same angle at different radii.

Lastly we check the cup on the trailing edge of the blade. We need to have the cup slightly higher than the leading or cutting edge for it to work efficiently. I have spoken about on another page on my web site, but for now let's think about the cup as being there to hold water pressure on the blades. If one cup is lower than the others we will find it to have a vibration effect.

So, how important is it to have the pitch measured accurately? Consider this, If I wanted to change pitch on a 15' diameter propeller I would have to physically twist the whole blade around approximately 2 mm to change 1' of pitch. Impact damage bends the blade alignment (rake) it won't twist the blades around.

Straighten the blades first then the pitch usually follows.3. The Backing Plate - This is a neat little concept. We clamp the backing plate into a vice in either a vertical or horizontal position. Our propellers are mounted to the backing plate in the vertical position for the straightening side of the repair and once we have finished we turn it to the horizontal position for the welding, sanding and finishing off process.4. Misc bits & pieces - Included in the box are several threaded rods and mandrels for mounting the propellers to the backing plate.

Ghostscript for mac. NOTE: Users of many dye sublimation printers must follow a special installation procedure. Support most Datamax-O'Neil DPL printers. Please read the release notes very carefully!.

You will also find a spacer and bushes for centralizing the propellers. Oh, and not to forget the steel ruler for measuring pitch.5. Measuring Software - You could do all the calculations to measure pitch manually but I created a neat little flash interface for entering the information into to give us our pitch. (see software specs below)What propellers will these tools work with?Nearly every outboard and most stern drive propellers on the market!

Yamaha, Mariner, Mercury, Evinrude, Johnson, Tohatsu, Suzuki, Honda, Chrysler, Volvo. Make some adapters up and repair Volvo Duo props, Mercruiser Bravo propellers etc. This little box contains a business nearly all boat shops could use.Other equipment required?

(not included)The main equipment you will require is an AC/DC TIG welder. The operation and use of a TIG welder is not included with this information.

These are readily available on eBay for less than $1000. A standard vice mounted to a work bench, 7' / 5' sanders, file, hammers, welding consumables and a pc to run the measuring software if required. Purchase the Propeller Blade Alignment Tool Construction Software. Cad Drawings. Tool Construction Videos. Pitch Measuring SoftwareDownload the CAD drawings in PDF format and brief construction videos so you can start building these tools straight away!

The videos describe how I built the Pitch Gauge, Rake Gauge, Mandrels and the Misc equipment required to use with them. Included are the 8 videos from our Youtube channel to view offline.

Also included is the pitch measuring software and an explanation on how it works plus a few of my extra tips that kept my sanity when I was running my own business. Software download Updated Jan 2019.The link to your purchase will be emailed to you within 24 hours of receipt of paymentClick this link to Purchase Software - Price $66.00 AUDSoftware Minimum System RequirementsWindows PC running xp and upAdobe ReaderNote: Due to OS advancement, web browser security settings and anti-virus interventions on newer PCs this package may require advanced user interactions to run or installing it.

As we are unable to supply advice for all scenarios. Important InformationBefore proceeding with purchasing please ensure you have read this article fully to understanding the limitations and advantages of the information. If you have any questions please contact me for further clarification.

The tools and software were designed to give reasonable accuracy in the repair of propellers to 20 inch in Diameter. If you are wishing to repair heavily damaged propellers, stainless steel or propellers to ISO standards then I would highly recommend purchasing an alternate propeller repair system using pitch blocks and computer measuring devices. The information I am providing is based on my own process of 'How I repaired propellers' in my own successful propeller repair business and you would need to investigate the suitability of this information, software and equipment for your own applications and country legal requirements. It does not, and is not intended to provide a complete understanding of all aspects of propellers repairs.

A true reading and comparison can be easily made against a new propeller. With experience a repairer should be able to achieve a very satisfactory result. Some manufacturer's sizes may be different from actual size measured because of progressive pitch and cup size. It is impossible to list every variable on this web site which would relate to the many scenarios you may come across. People’s lives are at stake if you send them out to sea with a faulty bush a poor blade repair or bad advice. You need to set your standards very high and let’s keep in mind the safety aspect of boating. Make sure you are competent enough in your advice and to make those decisions about what’s a safe repair and what should be basically thrown away.

Having said all that the system I used worked successfully for years in a professional propeller repair shop.The information in this article is subject to change without notice.

All props will be described by two numbers, such as 13 x 21. Those numbers are the diameter and pitch.

Diameter is the overall size of the blade as measured from the tips. A large diameter propeller can push more water than a small diameter propeller, creating more power. Diameter is predetermined by the manufacturer for a family of products. Your prop selection will be focused on the pitch.Pitch is the distance the propeller will move the boat after one revolution (not accounting for slip). A lower pitched propeller will create more power due to more engine RPMs, but the boat will move slower.

A higher pitched prop allows the boat to move faster by travelling a farther distance with each rotation. When choosing a propeller, choose a pitch that will keep the engine RPM in its recommended operating range. Going under the range will cause the boat to lug, while going over can cause engine strain.Blades have other important features built into their design. Rake is the angle between the blade and the hub. The rake angle can be flat, staying the same along the entire blade, or progressive, meaning the angle increases as it approaches the tip. Props have between 0 and 20 degrees rake. The rake angle determines how much the bow lifts out of the water.

High rake propellers are ideal for light-weight, high speed boats. Too much rake, however, will strain the engine and reduce overall performance.Some propellers are cupped, which means they have a lip on the edge of the blades. The cup creates more space between the sides of the blades, reducing ventilation and slippage. If the cup is on the tip of the blade, the blade has an increased rake angle and a higher bow lift.

If the cup is on the trailing edge, it effectively increases the pitch size, and the propeller will create more power at the cost of engine speed.Blades are also designed to prevent ventilation and cavitation. Ventilation is when air is drawn around the blades between the blade surface and the water. Ventilation increases RPM but reduces speed, especially during hard acceleration.

The anti-ventilation plate mounted on the outboard helps to prevent this problem. Cavitation is caused by water flow disturbances around the blades.

Disturbances cause water bubbles to boil and burst against the blades, which damages the surface and reduces performance.The fewer number of blades a propeller has, the more efficient it is. However fewer blades will also increase the 'vibration' you will feel.

That’s why three blade propellers are the most common for general purpose boating. Three blades props provide the best combination of performance, speed, and efficiency. Some manufacturers also create four and five blade propellers to increase acceleration and reduce ventilation. A four blade propeller will improve handling and control for high-performance applications. Five blade propellers are good for rough water conditions and tow sports.Finally, material is an important consideration for your propeller. Aluminum props are a great balance of cost, performance, and durability.

Stainless steel is five times stronger than aluminum, dramatically improving performance and durability. Stainless steel propellers offer better acceleration and are less likely to be damaged from striking objects in the water. Stainless steel props will outlast aluminum multiple times over.Left: a stainless steel propeller. Right: an aluminum propeller. How to Choose the Correct Pitch and Blade Count. Before you dive into choosing a propeller, understand your boat’s intended use.

Consider your average speed, load, and boating location. If you will be using the boat for multiple applications, you may need to switch props.

The propeller choice directly affects the engine RPM and therefore its performance. Choose a propeller that puts the engine RPM at the midpoint or higher of the wide open throttle (WOT) range with a normal load. This operating range will translate to the highest horsepower available from your outboard. Refer to your engine operating manual for the operating range.Once you know the operating range, consult the propeller guide for your engine to pick a combination of pitch, blade number, and material. Choose a range of propellers to perform a water test. Test the props under the same conditions that you would typically use the boat—same load, gear, and water. Set the trim angle so the boat has optimum speed on top of the water.To test the prop, run the boat at WOT and observe the maximum engine RPM on a tachometer.

If the RPM is below the recommended operating range, switch to a propeller with lower pitched blades. If the RPM is higher, switch to a propeller with higher pitched blades. Each inch of pitch size will change the RPM by 150-200 RPM. Aim for the midpoint or higher of the recommended operating range.

Keep in mind that high altitudes will reduce engine power, so choose a lower pitch to achieve the same RPM as on sea level.Engine height also affects the performance of the propeller. Once you find the right prop, adjust the engine mounting height to create the best balance between speed, maneuverability, and acceleration. Start with the anti-ventilation plate even with the bottom of the boat. Raise the engine one mounting hole at a time until performance is unacceptable, and then lower the engine one hole down.Keep a spare prop onboard for emergency situations. One recommendation is to buy a spare propeller that is two inches lower in pitch than your standard propeller. This reduction in pitch is perfect for tow sports, such as water skiing, due to a slower acceleration and higher power.

Popular Posts

Clamps, and pitch control mechanisms. This threatens propeller structural integrity and performance without being noticed. The overhaul calendar time periods for propellers are established so that the propeller can be disassembled to inspect internal surfaces. Moreover, corrosion acts continuously, regardless of the actual time in operation.

Ideal for small outboard shops, light engineering shops or the home handyman already familiar with welding. These simple tools are used in averaging out the propeller pitch and rake to give very speedy repairs. Practically all outboard and sterndrive propellers to 20 inches in diameter can be aligned with this kit.

(software measures props 9\' to 20\' although outside this range may be possible) This is a stepping stone for those who wish to get into the propeller repair industry at a low cost then move up to a more advanced system as their needs grow. What items are to be made / included in kits?1.

The Rake Gauge - Probably the most important tool in the kit! When we think of balancing a propeller we automatically think of weight balancing (dynamic). But it\'s way more important to have the blades straight and in alignment with each other (statically balanced). Blades that are bent or missing pieces will cause vibrations because they are not holding equal water pressure on each blade.

This tool assists in showing you where a propeller is bent and we can also use them to compare rake against new propellers.2. The Pitch Gauge - I use this after I align the blades. We have to ensure each blade is cutting through the water at the same angle at different radii.

Lastly we check the cup on the trailing edge of the blade. We need to have the cup slightly higher than the leading or cutting edge for it to work efficiently. I have spoken about on another page on my web site, but for now let\'s think about the cup as being there to hold water pressure on the blades. If one cup is lower than the others we will find it to have a vibration effect.

So, how important is it to have the pitch measured accurately? Consider this, If I wanted to change pitch on a 15\' diameter propeller I would have to physically twist the whole blade around approximately 2 mm to change 1\' of pitch. Impact damage bends the blade alignment (rake) it won\'t twist the blades around.

Straighten the blades first then the pitch usually follows.3. The Backing Plate - This is a neat little concept. We clamp the backing plate into a vice in either a vertical or horizontal position. Our propellers are mounted to the backing plate in the vertical position for the straightening side of the repair and once we have finished we turn it to the horizontal position for the welding, sanding and finishing off process.4. Misc bits & pieces - Included in the box are several threaded rods and mandrels for mounting the propellers to the backing plate.

Ghostscript for mac. NOTE: Users of many dye sublimation printers must follow a special installation procedure. Support most Datamax-O\'Neil DPL printers. Please read the release notes very carefully!.

You will also find a spacer and bushes for centralizing the propellers. Oh, and not to forget the steel ruler for measuring pitch.5. Measuring Software - You could do all the calculations to measure pitch manually but I created a neat little flash interface for entering the information into to give us our pitch. (see software specs below)What propellers will these tools work with?Nearly every outboard and most stern drive propellers on the market!

Yamaha, Mariner, Mercury, Evinrude, Johnson, Tohatsu, Suzuki, Honda, Chrysler, Volvo. Make some adapters up and repair Volvo Duo props, Mercruiser Bravo propellers etc. This little box contains a business nearly all boat shops could use.Other equipment required?

(not included)The main equipment you will require is an AC/DC TIG welder. The operation and use of a TIG welder is not included with this information.

These are readily available on eBay for less than $1000. A standard vice mounted to a work bench, 7\' / 5\' sanders, file, hammers, welding consumables and a pc to run the measuring software if required. Purchase the Propeller Blade Alignment Tool Construction Software. Cad Drawings. Tool Construction Videos. Pitch Measuring SoftwareDownload the CAD drawings in PDF format and brief construction videos so you can start building these tools straight away!

The videos describe how I built the Pitch Gauge, Rake Gauge, Mandrels and the Misc equipment required to use with them. Included are the 8 videos from our Youtube channel to view offline.

Also included is the pitch measuring software and an explanation on how it works plus a few of my extra tips that kept my sanity when I was running my own business. Software download Updated Jan 2019.The link to your purchase will be emailed to you within 24 hours of receipt of paymentClick this link to Purchase Software - Price $66.00 AUDSoftware Minimum System RequirementsWindows PC running xp and upAdobe ReaderNote: Due to OS advancement, web browser security settings and anti-virus interventions on newer PCs this package may require advanced user interactions to run or installing it.

As we are unable to supply advice for all scenarios. Important InformationBefore proceeding with purchasing please ensure you have read this article fully to understanding the limitations and advantages of the information. If you have any questions please contact me for further clarification.

The tools and software were designed to give reasonable accuracy in the repair of propellers to 20 inch in Diameter. If you are wishing to repair heavily damaged propellers, stainless steel or propellers to ISO standards then I would highly recommend purchasing an alternate propeller repair system using pitch blocks and computer measuring devices. The information I am providing is based on my own process of \'How I repaired propellers\' in my own successful propeller repair business and you would need to investigate the suitability of this information, software and equipment for your own applications and country legal requirements. It does not, and is not intended to provide a complete understanding of all aspects of propellers repairs.

A true reading and comparison can be easily made against a new propeller. With experience a repairer should be able to achieve a very satisfactory result. Some manufacturer\'s sizes may be different from actual size measured because of progressive pitch and cup size. It is impossible to list every variable on this web site which would relate to the many scenarios you may come across. People’s lives are at stake if you send them out to sea with a faulty bush a poor blade repair or bad advice. You need to set your standards very high and let’s keep in mind the safety aspect of boating. Make sure you are competent enough in your advice and to make those decisions about what’s a safe repair and what should be basically thrown away.

Having said all that the system I used worked successfully for years in a professional propeller repair shop.The information in this article is subject to change without notice.

All props will be described by two numbers, such as 13 x 21. Those numbers are the diameter and pitch.

Diameter is the overall size of the blade as measured from the tips. A large diameter propeller can push more water than a small diameter propeller, creating more power. Diameter is predetermined by the manufacturer for a family of products. Your prop selection will be focused on the pitch.Pitch is the distance the propeller will move the boat after one revolution (not accounting for slip). A lower pitched propeller will create more power due to more engine RPMs, but the boat will move slower.

A higher pitched prop allows the boat to move faster by travelling a farther distance with each rotation. When choosing a propeller, choose a pitch that will keep the engine RPM in its recommended operating range. Going under the range will cause the boat to lug, while going over can cause engine strain.Blades have other important features built into their design. Rake is the angle between the blade and the hub. The rake angle can be flat, staying the same along the entire blade, or progressive, meaning the angle increases as it approaches the tip. Props have between 0 and 20 degrees rake. The rake angle determines how much the bow lifts out of the water.

High rake propellers are ideal for light-weight, high speed boats. Too much rake, however, will strain the engine and reduce overall performance.Some propellers are cupped, which means they have a lip on the edge of the blades. The cup creates more space between the sides of the blades, reducing ventilation and slippage. If the cup is on the tip of the blade, the blade has an increased rake angle and a higher bow lift.

If the cup is on the trailing edge, it effectively increases the pitch size, and the propeller will create more power at the cost of engine speed.Blades are also designed to prevent ventilation and cavitation. Ventilation is when air is drawn around the blades between the blade surface and the water. Ventilation increases RPM but reduces speed, especially during hard acceleration.

The anti-ventilation plate mounted on the outboard helps to prevent this problem. Cavitation is caused by water flow disturbances around the blades.

Disturbances cause water bubbles to boil and burst against the blades, which damages the surface and reduces performance.The fewer number of blades a propeller has, the more efficient it is. However fewer blades will also increase the \'vibration\' you will feel.

That’s why three blade propellers are the most common for general purpose boating. Three blades props provide the best combination of performance, speed, and efficiency. Some manufacturers also create four and five blade propellers to increase acceleration and reduce ventilation. A four blade propeller will improve handling and control for high-performance applications. Five blade propellers are good for rough water conditions and tow sports.Finally, material is an important consideration for your propeller. Aluminum props are a great balance of cost, performance, and durability.

Stainless steel is five times stronger than aluminum, dramatically improving performance and durability. Stainless steel propellers offer better acceleration and are less likely to be damaged from striking objects in the water. Stainless steel props will outlast aluminum multiple times over.Left: a stainless steel propeller. Right: an aluminum propeller. How to Choose the Correct Pitch and Blade Count. Before you dive into choosing a propeller, understand your boat’s intended use.

Consider your average speed, load, and boating location. If you will be using the boat for multiple applications, you may need to switch props.

The propeller choice directly affects the engine RPM and therefore its performance. Choose a propeller that puts the engine RPM at the midpoint or higher of the wide open throttle (WOT) range with a normal load. This operating range will translate to the highest horsepower available from your outboard. Refer to your engine operating manual for the operating range.Once you know the operating range, consult the propeller guide for your engine to pick a combination of pitch, blade number, and material. Choose a range of propellers to perform a water test. Test the props under the same conditions that you would typically use the boat—same load, gear, and water. Set the trim angle so the boat has optimum speed on top of the water.To test the prop, run the boat at WOT and observe the maximum engine RPM on a tachometer.

If the RPM is below the recommended operating range, switch to a propeller with lower pitched blades. If the RPM is higher, switch to a propeller with higher pitched blades. Each inch of pitch size will change the RPM by 150-200 RPM. Aim for the midpoint or higher of the recommended operating range.

Keep in mind that high altitudes will reduce engine power, so choose a lower pitch to achieve the same RPM as on sea level.Engine height also affects the performance of the propeller. Once you find the right prop, adjust the engine mounting height to create the best balance between speed, maneuverability, and acceleration. Start with the anti-ventilation plate even with the bottom of the boat. Raise the engine one mounting hole at a time until performance is unacceptable, and then lower the engine one hole down.Keep a spare prop onboard for emergency situations. One recommendation is to buy a spare propeller that is two inches lower in pitch than your standard propeller. This reduction in pitch is perfect for tow sports, such as water skiing, due to a slower acceleration and higher power.

...'>Manual Procedure For Propeller Pitch Measurement(06.04.2020)Clamps, and pitch control mechanisms. This threatens propeller structural integrity and performance without being noticed. The overhaul calendar time periods for propellers are established so that the propeller can be disassembled to inspect internal surfaces. Moreover, corrosion acts continuously, regardless of the actual time in operation.

Ideal for small outboard shops, light engineering shops or the home handyman already familiar with welding. These simple tools are used in averaging out the propeller pitch and rake to give very speedy repairs. Practically all outboard and sterndrive propellers to 20 inches in diameter can be aligned with this kit.

(software measures props 9\' to 20\' although outside this range may be possible) This is a stepping stone for those who wish to get into the propeller repair industry at a low cost then move up to a more advanced system as their needs grow. What items are to be made / included in kits?1.

The Rake Gauge - Probably the most important tool in the kit! When we think of balancing a propeller we automatically think of weight balancing (dynamic). But it\'s way more important to have the blades straight and in alignment with each other (statically balanced). Blades that are bent or missing pieces will cause vibrations because they are not holding equal water pressure on each blade.

This tool assists in showing you where a propeller is bent and we can also use them to compare rake against new propellers.2. The Pitch Gauge - I use this after I align the blades. We have to ensure each blade is cutting through the water at the same angle at different radii.

Lastly we check the cup on the trailing edge of the blade. We need to have the cup slightly higher than the leading or cutting edge for it to work efficiently. I have spoken about on another page on my web site, but for now let\'s think about the cup as being there to hold water pressure on the blades. If one cup is lower than the others we will find it to have a vibration effect.

So, how important is it to have the pitch measured accurately? Consider this, If I wanted to change pitch on a 15\' diameter propeller I would have to physically twist the whole blade around approximately 2 mm to change 1\' of pitch. Impact damage bends the blade alignment (rake) it won\'t twist the blades around.

Straighten the blades first then the pitch usually follows.3. The Backing Plate - This is a neat little concept. We clamp the backing plate into a vice in either a vertical or horizontal position. Our propellers are mounted to the backing plate in the vertical position for the straightening side of the repair and once we have finished we turn it to the horizontal position for the welding, sanding and finishing off process.4. Misc bits & pieces - Included in the box are several threaded rods and mandrels for mounting the propellers to the backing plate.

Ghostscript for mac. NOTE: Users of many dye sublimation printers must follow a special installation procedure. Support most Datamax-O\'Neil DPL printers. Please read the release notes very carefully!.

You will also find a spacer and bushes for centralizing the propellers. Oh, and not to forget the steel ruler for measuring pitch.5. Measuring Software - You could do all the calculations to measure pitch manually but I created a neat little flash interface for entering the information into to give us our pitch. (see software specs below)What propellers will these tools work with?Nearly every outboard and most stern drive propellers on the market!

Yamaha, Mariner, Mercury, Evinrude, Johnson, Tohatsu, Suzuki, Honda, Chrysler, Volvo. Make some adapters up and repair Volvo Duo props, Mercruiser Bravo propellers etc. This little box contains a business nearly all boat shops could use.Other equipment required?

(not included)The main equipment you will require is an AC/DC TIG welder. The operation and use of a TIG welder is not included with this information.

These are readily available on eBay for less than $1000. A standard vice mounted to a work bench, 7\' / 5\' sanders, file, hammers, welding consumables and a pc to run the measuring software if required. Purchase the Propeller Blade Alignment Tool Construction Software. Cad Drawings. Tool Construction Videos. Pitch Measuring SoftwareDownload the CAD drawings in PDF format and brief construction videos so you can start building these tools straight away!

The videos describe how I built the Pitch Gauge, Rake Gauge, Mandrels and the Misc equipment required to use with them. Included are the 8 videos from our Youtube channel to view offline.

Also included is the pitch measuring software and an explanation on how it works plus a few of my extra tips that kept my sanity when I was running my own business. Software download Updated Jan 2019.The link to your purchase will be emailed to you within 24 hours of receipt of paymentClick this link to Purchase Software - Price $66.00 AUDSoftware Minimum System RequirementsWindows PC running xp and upAdobe ReaderNote: Due to OS advancement, web browser security settings and anti-virus interventions on newer PCs this package may require advanced user interactions to run or installing it.

As we are unable to supply advice for all scenarios. Important InformationBefore proceeding with purchasing please ensure you have read this article fully to understanding the limitations and advantages of the information. If you have any questions please contact me for further clarification.

The tools and software were designed to give reasonable accuracy in the repair of propellers to 20 inch in Diameter. If you are wishing to repair heavily damaged propellers, stainless steel or propellers to ISO standards then I would highly recommend purchasing an alternate propeller repair system using pitch blocks and computer measuring devices. The information I am providing is based on my own process of \'How I repaired propellers\' in my own successful propeller repair business and you would need to investigate the suitability of this information, software and equipment for your own applications and country legal requirements. It does not, and is not intended to provide a complete understanding of all aspects of propellers repairs.

A true reading and comparison can be easily made against a new propeller. With experience a repairer should be able to achieve a very satisfactory result. Some manufacturer\'s sizes may be different from actual size measured because of progressive pitch and cup size. It is impossible to list every variable on this web site which would relate to the many scenarios you may come across. People’s lives are at stake if you send them out to sea with a faulty bush a poor blade repair or bad advice. You need to set your standards very high and let’s keep in mind the safety aspect of boating. Make sure you are competent enough in your advice and to make those decisions about what’s a safe repair and what should be basically thrown away.

Having said all that the system I used worked successfully for years in a professional propeller repair shop.The information in this article is subject to change without notice.

All props will be described by two numbers, such as 13 x 21. Those numbers are the diameter and pitch.

Diameter is the overall size of the blade as measured from the tips. A large diameter propeller can push more water than a small diameter propeller, creating more power. Diameter is predetermined by the manufacturer for a family of products. Your prop selection will be focused on the pitch.Pitch is the distance the propeller will move the boat after one revolution (not accounting for slip). A lower pitched propeller will create more power due to more engine RPMs, but the boat will move slower.

A higher pitched prop allows the boat to move faster by travelling a farther distance with each rotation. When choosing a propeller, choose a pitch that will keep the engine RPM in its recommended operating range. Going under the range will cause the boat to lug, while going over can cause engine strain.Blades have other important features built into their design. Rake is the angle between the blade and the hub. The rake angle can be flat, staying the same along the entire blade, or progressive, meaning the angle increases as it approaches the tip. Props have between 0 and 20 degrees rake. The rake angle determines how much the bow lifts out of the water.

High rake propellers are ideal for light-weight, high speed boats. Too much rake, however, will strain the engine and reduce overall performance.Some propellers are cupped, which means they have a lip on the edge of the blades. The cup creates more space between the sides of the blades, reducing ventilation and slippage. If the cup is on the tip of the blade, the blade has an increased rake angle and a higher bow lift.

If the cup is on the trailing edge, it effectively increases the pitch size, and the propeller will create more power at the cost of engine speed.Blades are also designed to prevent ventilation and cavitation. Ventilation is when air is drawn around the blades between the blade surface and the water. Ventilation increases RPM but reduces speed, especially during hard acceleration.

The anti-ventilation plate mounted on the outboard helps to prevent this problem. Cavitation is caused by water flow disturbances around the blades.

Disturbances cause water bubbles to boil and burst against the blades, which damages the surface and reduces performance.The fewer number of blades a propeller has, the more efficient it is. However fewer blades will also increase the \'vibration\' you will feel.

That’s why three blade propellers are the most common for general purpose boating. Three blades props provide the best combination of performance, speed, and efficiency. Some manufacturers also create four and five blade propellers to increase acceleration and reduce ventilation. A four blade propeller will improve handling and control for high-performance applications. Five blade propellers are good for rough water conditions and tow sports.Finally, material is an important consideration for your propeller. Aluminum props are a great balance of cost, performance, and durability.

Stainless steel is five times stronger than aluminum, dramatically improving performance and durability. Stainless steel propellers offer better acceleration and are less likely to be damaged from striking objects in the water. Stainless steel props will outlast aluminum multiple times over.Left: a stainless steel propeller. Right: an aluminum propeller. How to Choose the Correct Pitch and Blade Count. Before you dive into choosing a propeller, understand your boat’s intended use.

Consider your average speed, load, and boating location. If you will be using the boat for multiple applications, you may need to switch props.

The propeller choice directly affects the engine RPM and therefore its performance. Choose a propeller that puts the engine RPM at the midpoint or higher of the wide open throttle (WOT) range with a normal load. This operating range will translate to the highest horsepower available from your outboard. Refer to your engine operating manual for the operating range.Once you know the operating range, consult the propeller guide for your engine to pick a combination of pitch, blade number, and material. Choose a range of propellers to perform a water test. Test the props under the same conditions that you would typically use the boat—same load, gear, and water. Set the trim angle so the boat has optimum speed on top of the water.To test the prop, run the boat at WOT and observe the maximum engine RPM on a tachometer.

If the RPM is below the recommended operating range, switch to a propeller with lower pitched blades. If the RPM is higher, switch to a propeller with higher pitched blades. Each inch of pitch size will change the RPM by 150-200 RPM. Aim for the midpoint or higher of the recommended operating range.

Keep in mind that high altitudes will reduce engine power, so choose a lower pitch to achieve the same RPM as on sea level.Engine height also affects the performance of the propeller. Once you find the right prop, adjust the engine mounting height to create the best balance between speed, maneuverability, and acceleration. Start with the anti-ventilation plate even with the bottom of the boat. Raise the engine one mounting hole at a time until performance is unacceptable, and then lower the engine one hole down.Keep a spare prop onboard for emergency situations. One recommendation is to buy a spare propeller that is two inches lower in pitch than your standard propeller. This reduction in pitch is perfect for tow sports, such as water skiing, due to a slower acceleration and higher power.

...'>Manual Procedure For Propeller Pitch Measurement(06.04.2020)